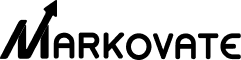

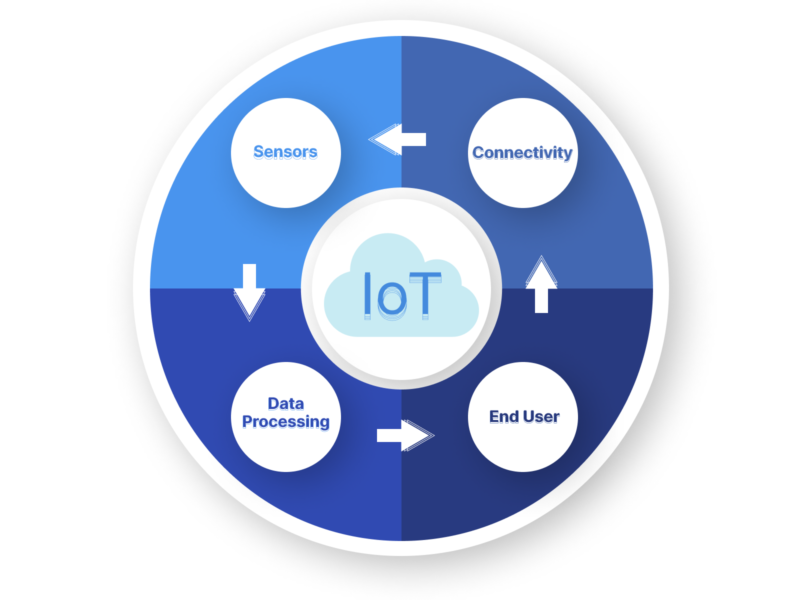

Digital transformation and IoT industrial automation have emerged as buzzing terms in the last few years. Businesses are looking for inventive and cutting-edge solutions to help their businesses grow and cater to their customer’s needs. With the aid of digital transformation, they hope to offer something fresh that wasn’t available a few years ago. A digitalized way in which they can reduce the manual workload and replace it with automated methods.

Enterprise digital transformation is necessary to keep up with varying user needs and technological trends.

To improve performance and make their infrastructure future-proof, it is crucial to integrate digital solutions. Digital transformations are the future, and people are looking for technology to be used in a way that is directly beneficial for them and helps them to achieve tasks that they earlier could not.

IoT industrial automation: A fuel for digital transformation

IoT app development service offers innovative solutions to overcome problems that crave automation. It can help in an overall better user experience, as it monitors the customer’s trends and patterns and what likely their next move will be. IoT devices also collect data and analytics from various devices, which can be fed into data analytics software to gain insights for prospects, which might not be visible otherwise. In the long run, these devices can also help to bring down operational costs significantly and help in better resource management.

This enables you to outperform rival businesses, stay completely in touch with user data, and carefully monitor their metrics. Undoubtedly, this technology prioritizes the user’s needs and implicit habits. IoT is a great technology that helps to come up with practical and analytical solutions to help your businesses judge and understand your user base thoroughly, which in turn helps them to function better overall as they know where to work on.

Further Read: 6 Steps To Kick-Start IoT App Development For Your Business

How does IoT work?

IoT devices operate under the premise that data transfers over networks should be possible without human intervention. These devices collect the data from the objects they are associated with (e.g., a heart monitor implant in a person which continuously sends the patient’s heartbeat, pulse, and other factors which determine whether the heart is functioning correctly or not) and send it so that it be acted accordingly. This data, which they acquire from the device’s domain, is collected with the help of embedded systems consisting of processors and microchips.

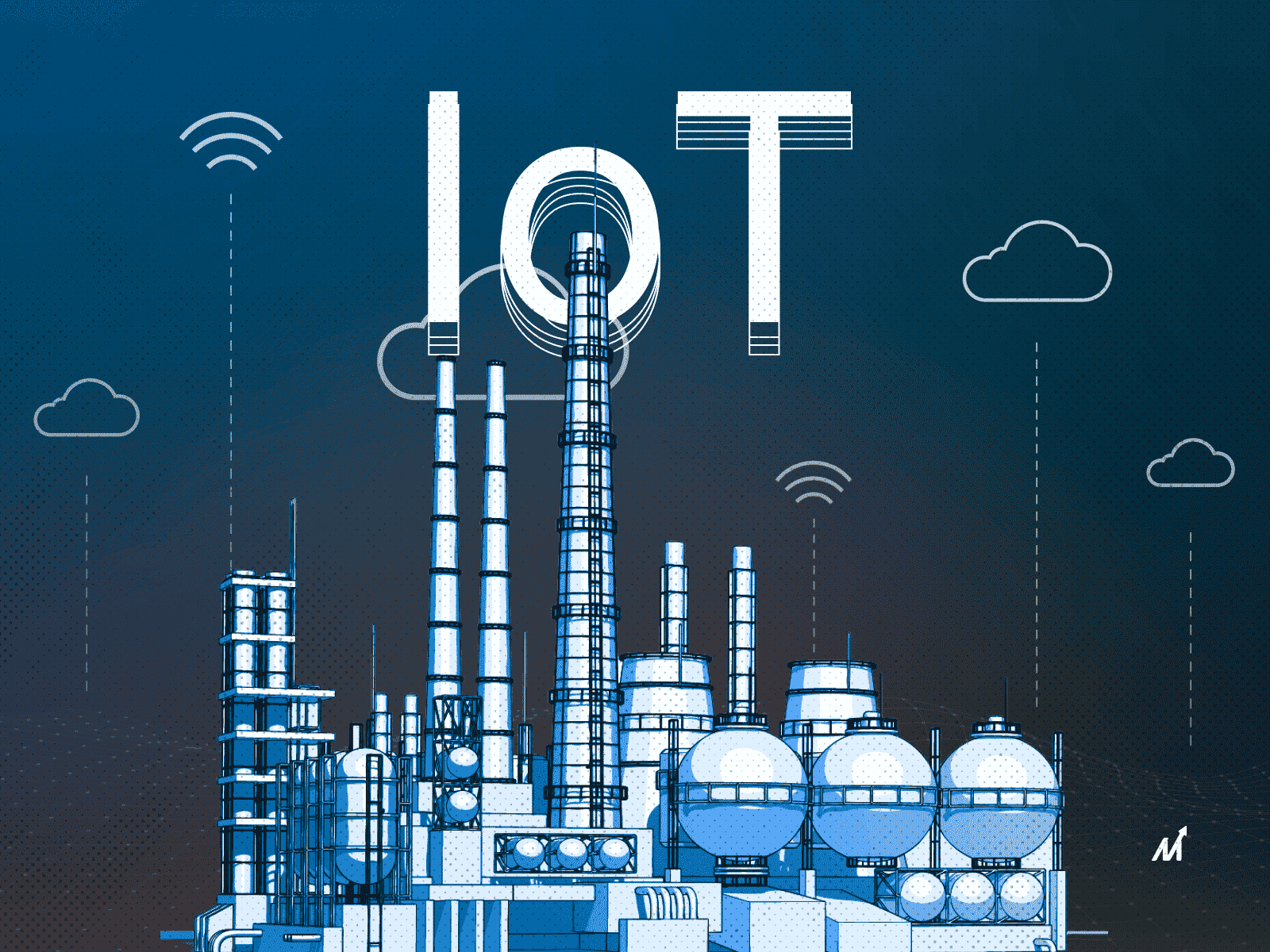

IoT devices form a whole ecosystem consisting of web-enabled smart devices, along with network protocols and applications, to form a network that makes the transmission and reception of data a convenient and independent process. This system mainly works with four components:

1. Sensors

These sensors are incorporated into the IoT devices and help collect complex data from their environment, such as our body temperature. Multiple sensors can also be coupled to compile data of varying degrees and then sent further.

2. Connectivity

Data transfer would require a medium to travel through, achieved by various networks. This might be subjective to the network connectivity in different areas, and thus it’s essential to choose the right one for a particular ecosystem. It can be through Bluetooth, Satellite, Wi-Fi, etc.

3. Data processing

This data is then sent to the cloud software to perform the required analytics. It might be to keep in check the health parameters, for example, or perform image processing to identify an object, according to which it’s sent back to the user or business team, who can then take the necessary actions.

4. End-users

This involves helping the data reach the end-users using the device and helping them to decide what they have to do next. It can be through triggers, notifications, or alerts. The decisions can also be automated for fixed scenarios, which can help eliminate human intervention. For instance, if the refrigerator temperature rises, it is automatically switched off.

Thus IoT is a complex architecture that helps to collect, send and analyze data using multiple domains to come up with the best-automated solution possible. It is no wonder it is indispensable in digital transformation and IoT industrial automation.

7 ways how IoT is revolutionizing the industrial automation

There are several ways in which the role of IoT has become of utmost importance when we talk about industrial automation and the impact it has made on different industries:

1. Helps businesses to utilize the latest technology

Industries have been around for a long time, and before IoT, many of their processes were largely manual and required a lot of labor, time, and effort. With the help of IoT automation, many processes are left to be done automatically by these devices. This helps them incorporate more effective solutions for achieving their goals and keeping up with the fast-paced world. IoT industrial automation has made the whole workflow seamless and reduced the need for human intervention, especially for tasks that are repetitive and can easily be automated.

2. Removes the manual errors

It is a human tendency to slip once here or there and make mistakes. It might be small or big, but it does hinder the functioning. With IoT devices, there is a reliability factor regarding functioning and accuracy. It would not require as much attention as required with manual processes, reducing the workload on industries and helping them focus on other, more important things.

3. Better customer experience

incredibly insightful. One can look into the metrics and make informed decisions, as the data comes from their users. This helps significantly improve the customer experience and, in turn, the business profits. A lot of times, there are essential factors that might not be detectable with the naked eye but can be obtained with the help of IoT devices.

4. Cost reduction

Costs can be saved tremendously in labor, security, and inventory management. All these domains can be optimized with the help of IoT. For instance, if an error occurs while delivering a product, it can automatically be detected by the device and sent back through an alert instead of an employee going all the way. Or, for security, instead of traditional video taps, you can use smart cameras connected to the internet and be put anywhere, making them scalable and saving on storage.

5. Operational efficiency

The workflow significantly improves when areas like logistics are fully automated. Employees can interact with their surroundings quickly and easily. There is a fully functional flow in the supply chain, and the industrial operations thus become smoother.

6. Improved strategies and decision making

The use of data by different software for obtaining useful information plays a crucial role in helping the owners identify the faults’ bottlenecks and can cater to them specifically. The minute data collection by the IoT devices does give the industries a larger picture of their products and functioning and helps them to make more effective and strategized decisions which would prove to be beneficial in the future.

7. Increases efficiency

IoT devices are highly efficient in monitoring and tracking and help automate processes that are too cumbersome to do so manually. The involvement of machines and technology helps significantly increase efficiency in any industry, whether aviation, healthcare, or energy.

Use cases of IoT in different industries

1. Healthcare

This is one of the prime sectors in which IoT technology is used. Glucose monitoring devices help to monitor patient glucose and warn the doctors if there is a significant fluctuation. Hearing devices that are synced through Bluetooth to your smartphone which has changed the way deaf patients can interact with the world. People are also working on mood-improving devices, which can signal our brain to improve if we are not feeling well.

2. Retail

Equipment maintenance or customer care applications are a few areas where IoT devices are used in the retail industry. For instance, the refrigerator’s temperature is equipped with sensors to ensure food safety, irrespective of temperature fluctuations.

3. Logistics

IoT can be used for inventory analytics to keep the users updated in real-time about the product details, where the product is right now, and by approximately what time it will arrive. It can also be used in GPS fleet management to ensure product delivery and driver safety.

4. Manufacturing

Integrating IoT solutions can significantly boost supply chain management and product development. The real-time data acquired can help to know the products’ expected output, the system’s accuracy, and insights into the real-time processes.

Conclusion

IoT app development is inevitable if you want to bring a significant change in the operations and working of your business and get insights into data that you could not have imagined a few years back. This cool technology has revolutionized almost every sector, and its demand is only increasing in the future. The rise of automation and its tendency for accurate and error-free processes has greatly reduced manual work. IoT industrial automation has become a revolution in which almost every sector is taking part. It has the potential to completely transform the working of each of them for the better!

FAQs

1. What is meant by industrial automation?

Industrial automation refers to the heavy integration of software and machines to control and automatize processes in various industries.

2. What is the difference between IoT and IIoT?

Industrial Internet Of Things (IIoT) and IoT (Internet Of Things) mainly differ in their applications. IIoT is used on a large scale for industries, while IoT is used on a smaller scale on devices such as home appliances, computers, etc.

3. What are the features of IoT?

Some significant features of IoT include AI, security, analyzing, active engagement, and connectivity.